Continuous improvement represents a vital competitive priority for leading organizations across nearly every industry. While crucial, cultivating a culture where improvement becomes ingrained as standard operating procedure requires diligence, commitment, and thoughtful change management. Employees often resist even well-intentioned modifications, let alone constant reinvention.

Leaders aiming to implement robust continuous improvement (CI) systems face tough obstacles in balancing worker expectations of stability with the dynamic flourishing enabled through ongoing enhancements. By carefully selecting and deploying research-backed lean methods tailored to their unique needs, organizations can effectively enable broad CI adoption.

This guide outlines evidence-based tips for launching new CI programs, as well as six proven lean continuous improvement tools and techniques for maximizing success. Learn how leaders around the globe spur relentless innovation by leveraging approaches pioneered inside Toyota’s famed production system. Before that though…

Where Should Your Lean Continuous Improvement Journey Begin?

Source: smartsheet.com

The most impactful continuous improvement initiatives stem from precise alignment on intended outcomes upfront. Rather than vaguely aiming to drive generic change faster, leaders should ground efforts in enhancing what already matters most. Here’s a step-by-step roadmap to help you structure pathways for progress:

- Map out current state operations in detail

- Identify gaps between existing function and ideal function based on purpose

- Brainstorm potential innovations to close largest gaps

- Prioritize solutions based on expected value added

- Test prioritized solutions sequentially using PDCA cycles

- Standardize positive changes and continue to new possibilities

While at it, periodically realign choices based on new needs and evolving purposes. For example, reflect on whether increased throughput, decreased cost, or greater customization now rank as more urgent priorities given market conditions. Iterate using the process above not just once, but continually.

6 Key Lean Continuous Improvement Tools and Techniques

Once you have a strategy to keep improving your operations and increasing value, you can look at some useful lean tools to help manage improvements. These include the following:

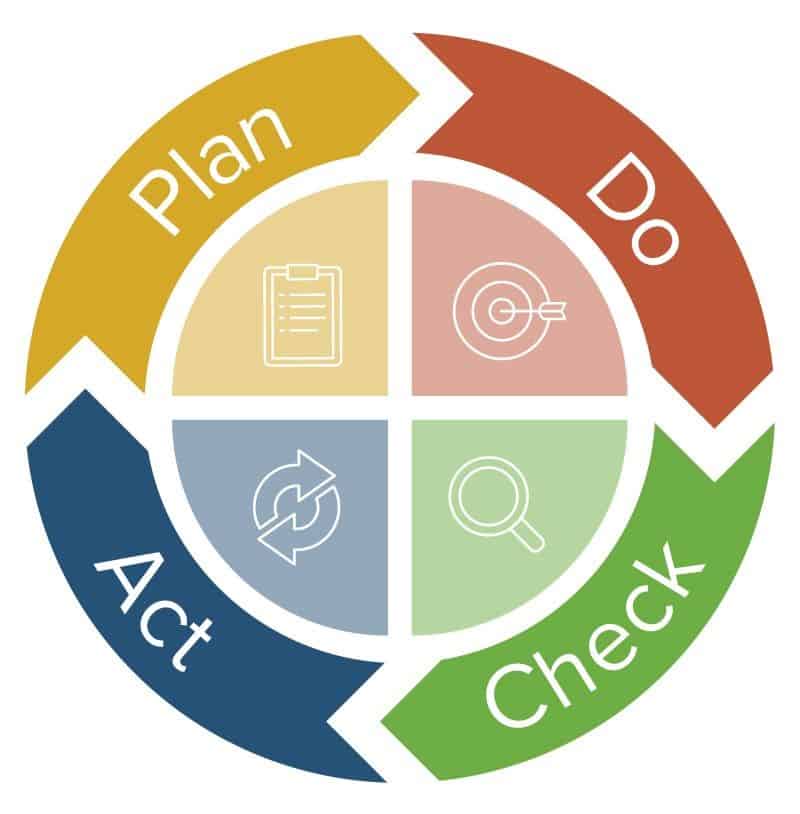

PDCA Cycles

The heralded Plan-Do-Check-Act methodology offers a blueprint for controlled experimentation of proposed changes. Leaders planning adjustments use PDCA to:

- Plan precise details around the change

- Do a small test case implementation

- Check results and impacts through defined metrics

- Act to standardize, amend, or abandon based on data

Rather than drastic, organization-wide shifts rolled out all at once, PDCA facilitates iterative evolution through calculated trials. It also provides structure for catching potential issues early and course correcting accordingly.

Kaizen Events

Kaizen concentrates change efforts into rapid, highly focused improvement projects targeting specific processes. Cross-functional teams drill down into root causes using other lean tools, then brainstorm innovative countermeasures.

Short bursts of intense Kaizen acceleration supercharge CI efforts between longer periods of standardized stability so employees can sustain newly elevated performance levels. Frequent Kaizen events then help to institutionalize forward momentum.

Gemba Walks

Source: isixsigma.com

The phrase “gemba walk” translates loosely to “go see for yourself” in Japanese. By frequenting the actual shop floor interacting directly with front line employees, leaders gain true appreciation for realities on the ground while building trust. Moreover, they gain more clarity around problems and ideas from those doing the work firsthand.

Removing management from isolated offices into raw observation and conversation opens pathways allowing grassroots enhancements to bubble up. Front-line insights better inform strategy decisions and change initiatives.

Asking “5 Whys”

This simple but surprisingly effective root cause analysis tactic pushes past surface symptoms to reveal deeper reasons behind operational problems. Leaders drill down repetitively asking some variation of “why does this problem happen” until reaching root causes. Answers at each level inform the next round of inquiry.

For example: The machine unexpectedly powers down, delaying production by 15 minutes (problem).

- Why did the machine power down? The attached power source safety overloaded (cause).

- Why did overloading happen? The compressor and drier simultaneously cycled on, exceeding capacity (deeper explanation).

- Why did both cycle simultaneously? The scheduling algorithm fails to sequence properly (root).

By repeatedly probing, leaders reveal less obvious but more fundamental drivers so they might eliminate recurrence through systemic solutions.

Mapping the 3Ms (Muri, Mura and Muda)

Wasteful dynamics manifesting as overburden, unevenness, and non-value activity permeate operations when unchecked. Here’s the translation from original Japanese terms:

- Muri: Overburden from deficient planning or insufficient capabilities

- Mura: Inconsistency causing unpredictable downstream waste

- Muda: Non-value actions themselves (defects, excess motion, etc.)

All three classes interconnect in dysfunctional ways. For example, overstaffing a line (muri) increases the likelihood of idle workers with low engagement sliding quality (muda). On the other hand, excessive pressure on understaffed groups (muri) prompts variability in workmanship and output volume (mura).

Constructing Value Stream Maps

This increasingly digitized visualization documents all process activities throughout an operational sequence, distinguishing between value-added vs non-value-added steps. Maps capture vital process attributes like cycle times, quality levels, production volumes, changeover rates, and workflow interconnections.

Leaders gain a shared understanding of systemic interdependencies helping drive global optimizations. By enhancing the helicopter perspective, they prevent isolated local changes that inadvertently sub-optimize performance overall.

Source: solvexia.com

Conclusion

Leading companies stay ahead by continually improving even wildly successful products, services, and systems before the competition makes them obsolete. Yet realizing such dynamic evolution hinges completely on internal cultures equally committed to progress.

Tap the motivational power within employees already inclined to take pride in shared accomplishments. The end goal is to guide internal change agents towards obsessive adjustment until it becomes as natural as breathing. Consistent evolution becomes the only constant. Good luck.